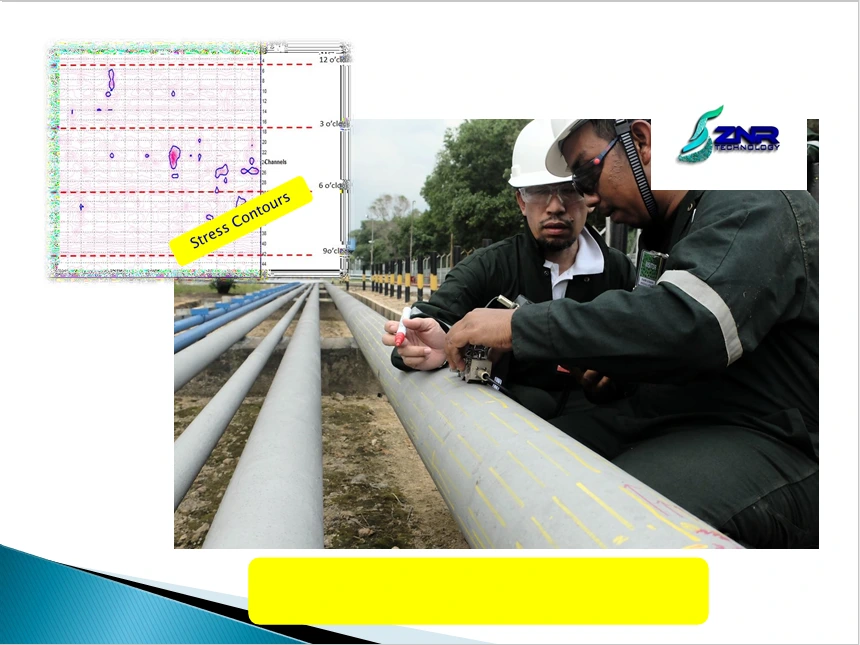

In this area of business, we are focusing on providing services utilising basic NDT and

advanced NDT. Specifically, we are offering services in the non-destructive testing

(NDT) services and also in the area of integrity monitoring, analysis and assessment.

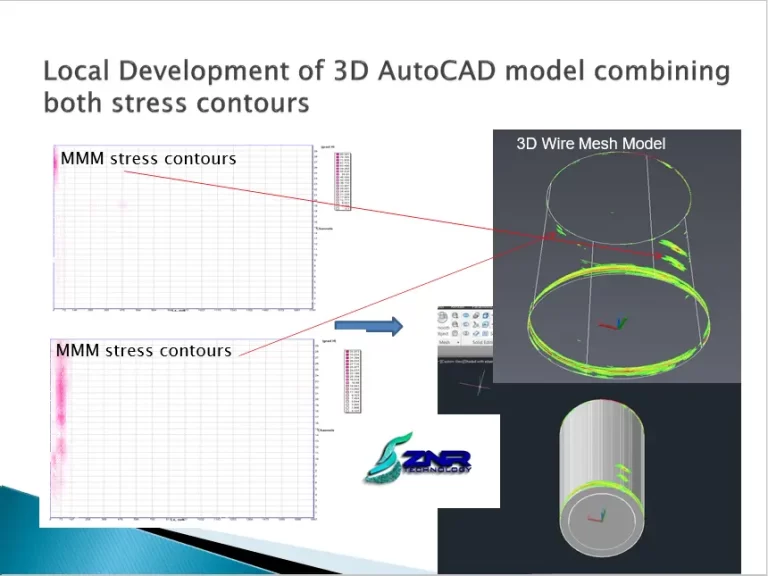

ZNRTSB is also the expert in the newly developed advanced NDT technology called

Strain-Stress Technology in Malaysia and South Asian Region.

For basic NDT, we are providing technology services based on Ultrasonic Testing (UT),

Radiography Testing (RT), Eddy Current Testing (ECT), Magnetic Particle Testing

(MPT) and others basic or conventional NDT technology in fulfilling the requirement

of engineering integrity assessment. We’re also providing man-power and services for

inspector in welding, QA/QC, API 510, API 570 and API 653.

© 2023 ZNR TECHNOLOGY SDN BHD | DIGITAL ENGINEERING INTEGRITY ASSESSMENT SOLUTION SOLAR & WIND POWER ENERGY

Design and Developed by Done 5 Technologies